MicroPerfection®The Science of Invisible Sound Control

Patented MicroPerfection® technology represents a revolutionary leap in acoustic panel performance. MicroPerfection® is the groundbreaking micro-perforation technology responsible for SoundPly panel’s exceptional resonant sound absorption. By precisely engineering microscopic perforations, an unparalleled level of sound absorption without compromising aesthetics is unlocked.

The development of micro-perforated sound absorption technology introduces an entirely new approach to sound absorption.

1. QUALITY OF MICRO-PERFORATIONS

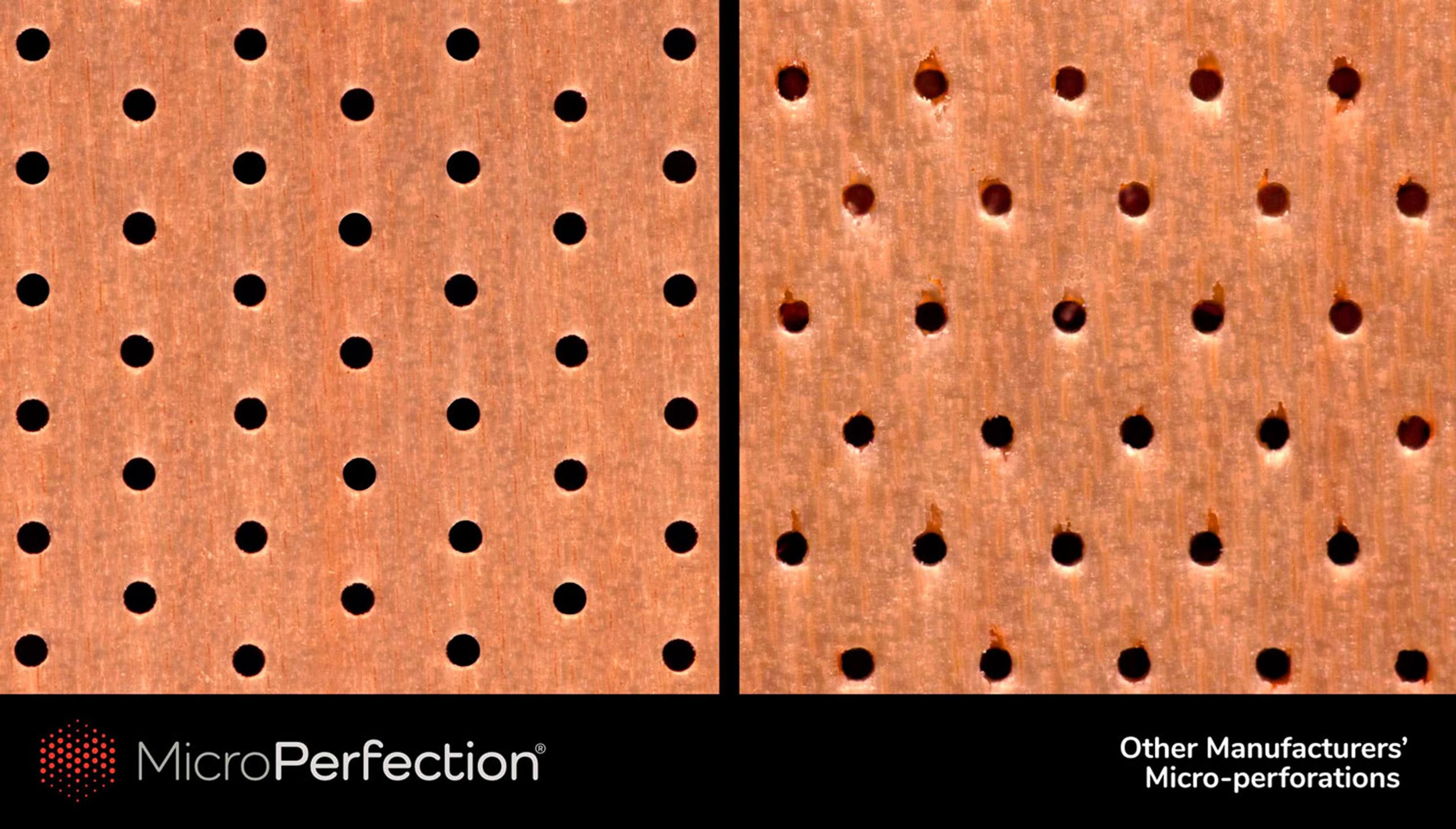

20x Magnification of

.5mm Micro-Perforations

The benefits of our proprietary broach pin punch process include clean, sharp holes, helping to avoid the “punch craters”, veneer tear-out, and rounded, light-reflecting edges synonymous with other manufacturing methods.

The Problem: Most wood MPPs sold in North America have micro-perforated veneer faces manufactured using a punch perforating machine. The punching process crushes the wood veneer, resulting in coarse micro-perforations with fractured passages, which disrupt and restrict the resonating airflow. This process is akin to using a hammer to remove the core of an apple—sure, a hammer can effectively remove the core, but it’s not ideal.

Laser cut micro-perforations typically featured by European and Asian manufacturers of MPPs are more precise than punching, but introduces its own issues, potentially scorching or burning the wood veneer due to heat accumulation. Both methods result in less-than-ideal quality and appearance, affecting long-term durability.

SoundPly’s Solution: MicroPerfection® employs a proprietary process using a sequence of broaching pins to create and refine each micro-perforation. “SoundPly panels feature MicroPerfection® technology, resulting in the most advanced, effective micro-perforations ever integrated into an acoustic panel. Achieving maximum acoustic performance required engineering a process to precisely manufacture a new type of micro-perforation—one that’s smaller, cleaner, and three times deeper than any currently produced.” This precision engineering results in the cleanest, sharpest, most uniformly shaped micro-perforations possible, maximizing airflow and resonant absorption. “Therefore high viscous energy dissipation takes place near the sharp edges.”

2. PERCENTAGE OF FUNCTIONAL MICRO-PERFORATIONS

The Problem: Traditional MPPs are constructed with bored MDF or particleboard cores. These boreholes range in diameter from 5/16” to 3/8”. The unbored areas of the panel’s core fully block a majority of the panel’s micro-perforations, entirely eliminating the sound absorbing role of those micro-perforations. Tests show that blocking just 5% of a panel’s micro-perforations results in a measurable reduction in the panel’s sound absorption. Surprisingly, less than 34% of other manufacturers’ micro-perforations are functional micro-perforated panels with bored cores.

SoundPly’s Solution: SoundPly’s patented construction (U.S. Patent No. 9,691,370 B1) utilizes a unique core structure and manufacturing process that ensures all micro-perforations are clear and unobstructed. This allows for near 100% functionality (99.97%), maximizing the panel’s sound absorption capabilities.

The Problem with Bored-Cores

Bored MDF is the industry’s standard

core for micro-perforated panels,

even though it renders two-

thirds of the micro-

perforations non-

functional.

3. DIMENSIONS OF MICRO-PERFORATIONS

A Cross-Section Comparison

The image above is an actual cross-section of the micro-perforated skin of Navy Island’s SoundPly, compared to the micro-perforated skin of other micro-perforated panels.

The Problem: The depth of the micro-perforations plays a critical role in resonant absorption, especially at lower frequencies. Due to the inherent limitations of punch and laser technologies when working with deeper micro-perforations, most MPPs have shallow micro-perforations, limiting their effectiveness. Many have depths as shallow as 0.5mm, resulting in 45% poorer broad frequency resonant absorption, compared to SoundPly’s micro-perforations.

SoundPly’s Solution: SoundPly’s micro-perforations are precisely engineered to be two to three times deeper than those of competing products (1.8-2.1mm deep vs. <0.7mm). This increased depth maximizes surface area for sound absorption and promotes more effective vortex shedding at higher SPLs (a key element of SoundPly’s Dynamic Sound Control™ technology).